Rick's b.log - 2017/01/06

You are 13.58.239.56, pleased to meet you!

Rick's b.log - 2017/01/06 |

|

| It is the 3rd of December 2024 You are 13.58.239.56, pleased to meet you! |

|

mailto: blog -at- heyrick -dot- eu

The oscilloscope is calibrated to match the frequency response of the croc clip probes. Calibration is performed by altering a capacitor trimmer to adjust the capacitance that appears between the input probe and the ground probe. Incorrect calibration means higher frequency signals will either have rounded edges, or 'bounce' afterwards.

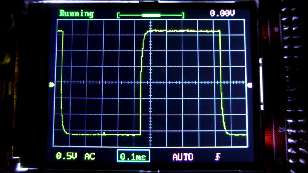

Here's an example of too much, and it's obvious what's wrong with this:

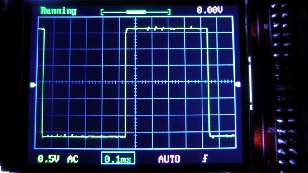

This is what the signal is supposed to look like:

Now, if I had a bare circuit kicking around, there would be no problem with capacitance. Getting to the trimmers is easy, but the device is utterly unprotected so really it needs to be in a case. Somebody that spends an afternoon building something moderately complex and doesn't put it in a box afterwards is asking for a world of disappointment.

But if it's in a box, how does one get to the trimmers?

One doesn't.

Unless one happens to have a small rounded grinder ball on a stick (actually designed for engaving glass!) and a smallish power drill. Then one can make a god-awful mess with little bits of plastic (detritus from the drilling) all over the place. Such a mess I had to strip the case right down to clean it all out. On the up side, I worked out where that other bit was supposed to go, so I've built it correctly now. ☺

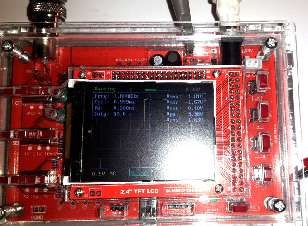

If you look carefully, you'll see two small holes to the left of the LCD.

Here's a closer-upper:

It's a shame that I didn't get them lined up nicely, but it was done freehand using a power drill, so it's not so bad. It achieves the aim of a hole into which a small screwdriver may be inserted to allow the trimmer to be twiddled.

Mod my 'scope

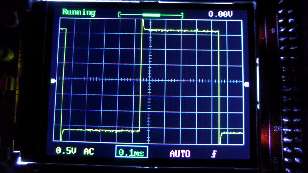

Here's an example of too little, note the rounded edges:

The upper trimmer (C6) is for the 1V range, and the lower trimmer (C4) is for the 0.1V range. There's no adjustment for the 10mV range.

David Pilling, 6th January 2017, 23:04

It would be nice to replace the trimmers with reverse biased diodes (the ones with lots of capacitance - varicap diodes) and have the software sort out the trimming.

Wonder if there is any customisation of this scope going on - I'd be thinking how to do screen shots and how to get data out of it.

| © 2017 Rick Murray |

This web page is licenced for your personal, private, non-commercial use only. No automated processing by advertising systems is permitted. RIPA notice: No consent is given for interception of page transmission. |