Rick's b.log - 2020/06/07

You are 3.144.4.54, pleased to meet you!

Rick's b.log - 2020/06/07 |

|

| It is the 24th of November 2024 You are 3.144.4.54, pleased to meet you! |

|

mailto: blog -at- heyrick -dot- eu

I tried to reduce the width of the text for IPv6 addresses, but it seems that Firefox on Android is bugged - it will reduce the width using the scale argument, but when working out placement and table cell sizes, it does all of that before reducing the width. So I'm just going to leave it as is and you'll see a ridiculously long IP address.

I trust IPv4 will be retained for use on LANs. Somehow I find it easier to remember that my printer is

By the way, don't thank me for this - thank Rob. Please prod the Donate button (on the right, or at the bottom in mobile mode) to send Rob a little thank you. Remember, this is for him. Not me. He deals with all the technical stuff and manages the hosting. I just write the rubbish you're reading now. ☺

I believe in the principle of "little and often", because "tidying the potager" is a daunting task, however when broken up into little bits and done piece by piece, it takes like ten times longer but the difference is that it gets done. Rather than me thinking "to hell with this" and writing something for my blog instead...

Yesterday's job was to tidy a bit of mess under the Epic Willow. Here's a before:

And here's the after:

There was some weird sort of ground-growing creeping pine plant that used to be all along there, but it has long since died. I think it was a victim of the hot summer/freezing winter circa 2003. It may have gone, but it has left many pieces of hard branches of wood behind. It also looks as there's a mess of wood bits cut up that was originally a pile now encumbered in weeds. I'm guessing mom might have done that a few years ago?

I wasn't done with that. I went up to the potager with manual hedge trimmers (think large scissors) and dealt with the remaining bramble.

I've not been able to take the mower to cut and mulch the brambles because, as you can see, there are all sorts of things there. Planters, plant pots, rocks... It'll need to be gone over manually inch by inch before I take either mower anywhere near that.

Turns out, as soon as I set it to perform a kneading cycle, the belt shredded itself into a gummy mess. Seems to be something of a pattern with old bread makers...

I'm not going to concern myself with the processor board. Two buttons, a handful of LEDs, and a microcontroller. Not much to examine there as much of the work is done as black-box firmware.

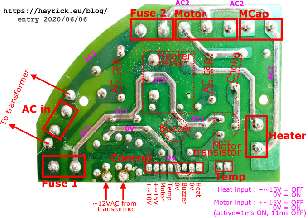

Here's an annotated version of the driver board:

I would imagine that this is being done to regulate the speed of the motor. It would complicate motor control (as it needs timed, rather than just switched on and off), but on the other hand it does open the possibility of variable motor speeds.

Looking from a safety viewpoint, I can't imagine active low is particularly good. I hope the outputs are weakly tied high and driven low, so at least if something on the controller board blows, it won't fall to zero and mean that stuff turns on.

It's also worth noting the uneasy mixing of high voltage and low voltage on the board. Take a look at the +~15V supply pin, and note that it is actually directly connected to AC1. This may explain what's going on with the buzzer (also connected to AC1). It may well be that the 0V is actually a false 0V, and the +~15V is a real 0V reference, with everything actually offset from that. It reminds me of the old "live chassis" televisions (where the receiver's ground was derived by rectifying live mains).

How did I determine what 0V was? Simple, it's the one connected to the VSS pin on the microcontroller. Everything was measured relative to that. But, it seems, it is never that simple...

IPv6

You may notice something odd in the "pleased to meet you" message in the title.

For some of you, it may look like this:

192.168.1.14 rather than 2a01:cb08:89 um uh... 382jsdjvj938fvlijf9084330985£$&$£$£} or something.

More tameage

I don't know if "tameage" is a word. It is now.

Still, it's another section that can eventually turn to grass to be looked after by Marte.

You can also see (the brown area) what I cut down last week. It was a mass of nettle and bramble almost as tall as I am. So seeing the back wall of the wood shed is an achievement... however like all the rest, the plan is to clear the area so Marte can give it a pass. Looking at the size, it might take four passes. Which ought to be about two or three minutes. You can see the plan...

Bread maker controls

I thought I'd take a look at how my smaller bread maker is actually controlled.

I have ordered a replacement, but since my model of bread maker doesn't seem to exist on any spares/parts site in France, I've made a guess by measuring the belt size and ordering something similar.

Either it will work, or it won't. If it doesn't the breadmaker will be discarded. So... we'll see.

Instead, let's imagine the controller doesn't exist. Say, say we want to replace it with some switches to do the same things. What would be necessary? How does the controller actually control the hardware?

Power supply

AC, nominally 230V, is provided directly to the board. It passes in two directions - one path towards the heater relay, and the other towards the motor control transistor. Both are independently fused using a thermal fuse attached to outside of the oven casing.

The mains is tapped off to a transformer that nominally returns 12VAC. This is then rectified via diodes and possibly a zener or two in order to provide two DC supplies, one at +~10V and the other at +~15V.

It's actually a fair bit weirder than this, see the end for a discussion.

Temperature control

This is a simple thermistor. It measured ~140KΩ at ambient temperature. When I put my finger on it, the resistance started to decrease, heading towards ~120KΩ at finger temperature.

One leg of the thermistor is tied to 0V.

Heater

AC for the heater passes through a large relay. When the relay is actived, the heater turns on.

An oddity is that the control output floats at +~15V, dropping to 0V when the heater is to turn on, that is to say, it is an active low signal (but read the end for a discussion on this).

Motor

AC for the motor passes through a triac (not a transistor actually, though the behaviour is ostensibly similar), and then to the motor via a three wire connection, one of the wires carrying pure AC and another carrying AC via a capacitor.

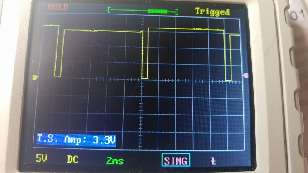

As with the heater, it is active low but with a quirk. The output is pulsed low (on) for 1 millisecond, followed by a 9 millisecond pause (not 11 as shown in the picture, I can't count!).

Here is the 'scope trace of the motor control signal while the motor was running continuously.

I wonder how fast the motor can actually go?

Buzzer

It's a standard piezo buzzer, so it ought to receive a square wave or something. That's not what I saw on my 'scope, however I didn't dig too deeply as it looks for all the world like the piezo is wired up between a control signal and one of the connections of the mains. WHAT?

An interesting thing to note is that the rated operational temperature of pieze buzzers usually tops out around +45°C. This one is on a PCB within in a plastic casing and about five centimetres away from an unshielded oven...

Discussion

Well, I was expecting on/off controls, active high, and a square wave for the buzzer. So what is actually going on is somewhat surprising.

John, 8th June 2020, 12:15 J.G.Harston, 9th June 2020, 01:25

| © 2020 Rick Murray |

This web page is licenced for your personal, private, non-commercial use only. No automated processing by advertising systems is permitted. RIPA notice: No consent is given for interception of page transmission. |