The type of motors used within

RickBot

There are

two main types of direct current electric motor

in the world...

Standard

motors

The first type of motor is the

standard sort of motor where you apply a voltage and it

starts to turn. This type of motor only has two wires

coming out of it.

These are dead easy to interface.

Some transistors and/or relays to switch the power on

and off, and cater to current reversal to handle

'backwards'.

Unfortunately these motors suffer

because tolerances and rotational speeds (usually being

dependent on the applied voltage) provide no guarantee

that two motors will turn in the exact same

way. The effect of this would be 'wandering'.

Robotic

devices using standard motors come in two forms. Either

one motor drives both back wheels, and turning

is implemented by changing the angle(s) of the front

wheel(s). Or one motor controls one rear wheel and

sophisticated methods try to ensure that the device

doesn't wander... (or otherwise the designer says "to

hell with it" and allows for these intolerances in the

design).

Stepper

motors

The second type of motor is the sort

where to apply a voltage to the motor and it may turn a

fraction before 'freezing' in a fixed position. Usually

has four or five wires coming out of the motor.

These

are a lot more complicated to interface because they

work by alternating power to specific windings within

the motor in a specific sequence.

These motors

provide a fine degree of control. Each 'pulse' steps the

motor one time in the nominated direction. One step

could be something like 7.5º, so it'd take 48 steps to

turn full circle. As you have to explicitly step these

motors, assuming the loading doesn't stall the rotor,

you will always know exactly how much the motor has

moved, and it will be possible to keep everything in

perfect synchronisation for hours - of course,

practically every printer available from humble yet

noisy dot matrix models to freaky-smelling laser

printers use stepper motors for precise placement of the

paper and the print head (or laser beam).

A

disadvantage of stepper motors is that high torque

motors are a lot harder to come by than their standard

counterparts. For example, if battery life was no object

we could build a robot using two car starter

motors. These motors can turn an engine, so dragging

heavy stuff behind the 'bot shouldn't be too hard. Now,

where would I easily obtain stepper motors

larger than those used within photocopiers and the

like?

Now for another advantage - applying a fixed

current to a fixed part of the coil will 'lock' the

motor. This feature could be used as a crude form of

'brake'.

And... another advantage. Because we move

the motor in steps, our chosen stepping rate will

directly affect the speed. To do this with a

standard motor requires pulse width modulation. Not so

different, but less precise.

A further complication

of stepper motors

Many types of this motor

exist, such as the delta configuration. We shall not

concern ourselves with this, because it is like saying

the Wankel engine exists ... it does, but how

many people in school mechanics class have actually

every seen one in real life, as opposed to a

diagram in a book or a little model.

There are two

main types of stepper motor and each have plus points

and minus points.

The first type of stepper motor

is the unipolar design, where the four

'poles' are two windings which are centre-tapped. The

centre tap is usually connected to the +ve supply

and we ground the required parts of the windings to

energise them and set up magnetic currents. By switching

which poles are magnetised, you can cause the motor to

turn. Reverse the direction of the stepping, the motor

turns the other way.

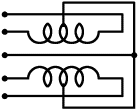

Here is a schematic

representation of this type of motor:

The second type of stepper motor

is the bipolar design, which is similar to the

above with two windings, only without the

centre tap. This means you can wind the motor core in a

more efficient way. A bipolar motor built on the same

frame as a unipolar motor will deliver 35%-45% higher

torque. The big complication is that these motors

require polarity adjustment. Let's say coil #1 requires

+ve on the left and -ve on the right to turn clockwise a

step. Well, to go counter clockwise we'd need to apply

-ve to the left and +ve on the right. This is usually

achieved by a design known as an 'H bridge'

(actually, most cheat and use and IC!) to flip the

polarity as required.

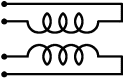

Here is a schematic

diagram:

What type of motor do we

use?

Within

RickBot, we shall be using two

unipolar motors with a 7.5º step angle. This is

purely because it is what I happened to salvage from an

old printer. In any case, the outputs from the

Amélie board are identical: left motor

direction, left motor step, right motor direction, right

motor step. It is possible to drive either type of

stepper motor from this.

As it stands, the application

code uses Timer2 to generate interrupts after the

desired time interval has passed, to control the motor

stepping. You could try hooking the

step signal through a power transistor to

directly switch a standard motor if you'd prefer to use

one of

those.