|

Possibilities

This section describes things

that could be added to RickBot's

sensing. Find out more; as well as

information on the options selectors - which

doesn't really have a section of its own to fit

into.

The options

switches

It may be desired that slight

modifications be made to the operation of the application

code. Now there are two ways you can do this.

The hard way is to hardwire the modifications,

make a set of firmware files, and program a set of

EPROMs. When you want a different behaviour, pick the

EPROM with the required options and plug it in.

The

easy way, however, is to plug

a SIL switch, or a set of jumpered links, into the

expansion port. This contains eight switches that can be on

or off, memory-mapped. The application code reads this, and

sets its behaviour according to those switches.

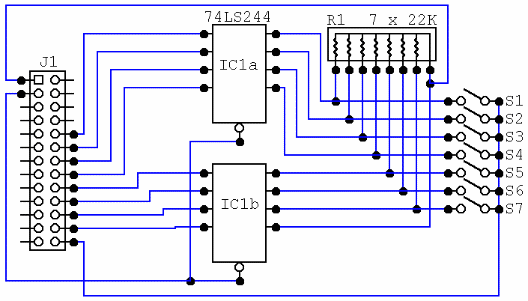

Here is a schematic for this:

The

eighth input is connected directly to +5V in order that the

application code detect the options board is present. It

is wired to UNUSEL (at

&A200). An easy

method of detection is to check &A200, &A210, and &A220. What is read back

from all three locations will be identical if the board

is connected - because the address lines are not

connected to anything so the response will be the

same.

The following

options are defined:

|

Switch |

OFF action |

ON action |

|

SW1 |

Line tracking

disabled. |

Line tracking

enabled. |

|

SW2 |

Track

black line on white

. |

Track

white line on black (inverted)

. |

|

SW3 |

currently

unassigned |

currently

unassigned |

|

SW4 |

currently

unassigned |

currently

unassigned |

|

SW5 |

currently

unassigned |

currently

unassigned |

|

SW6 |

currently

unassigned |

currently

unassigned |

|

SW7 |

currently

unassigned |

currently

unassigned |

At this stage, the behaviour

when no options board is connected is

undefined. It is likely that the application code will

simply behave as if all switches were in their

off position.

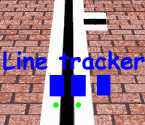

Marking the end of the guide

track...

An additional extension is the

implementation of a third sensor, offset to the

left (or right) of the others. This could be used

to sense an end of trackmarker, perhaps as shown in the diagram to the

right. An additional extension is the

implementation of a third sensor, offset to the

left (or right) of the others. This could be used

to sense an end of trackmarker, perhaps as shown in the diagram to the

right.

In this case, the third sensor

will be connected via a logic gate to switch on

both the left and right sensor signals (PA4 and PA5

).

As you can see, the end-of-guide

marker is a sideways version of the guide track. This is

to provide a strong ON-OFF-ON signal to the application

code; because the third sensor - looking down over the

ground - may receive numerous false readings. By knowing

the motor speed, it should be possible to set up a

response based on time (which, in turn, is based on

speed). Thus, it could be ON ~30ms, OFF ~30ms, ON

~30ms. |